Cuprins

- 1. PROJECT DESCRIPTION 5

- 1.1. BRIEF HISTORY OF LIFTS 5

- 1.2. OBJECTIVES OF THE PROJECT 6

- 1.3. MARKET ORIENTATION 7

- 1.3.1. One speed elevators 8

- 1.3.2. Two speed elevators 8

- 1.3.3. Variable speed elevators 8

- 1.4. DESCRIPTION OF THE INSTALLATION 10

- 1.4.1. Main structure 10

- 1.4.2. Traction group 13

- 1.4.3. Protection box 14

- 1.4.4. Control Panel 14

- 1.4.5. External and internal doors 15

- 1.4.6. Security 16

- 1.5. DESCRIPTION OF THE COMPONENTS 18

- 1.5.1. Electrical protection devices 18

- 1.5.2. Conductors 22

- 1.5.3. Lights 22

- 1.5.4. Plugs 25

- 1.5.5. Protective earth 25

- 1.5.6. Buttons 25

- 1.5.7. Contactors 27

- 1.5.8. Power supply 28

- 1.5.9. PLC 29

- 1.5.10. Door control 30

- 1.5.11. Positioning system 30

- 1.5.12. Emergency battery 35

- 1.5.13. Security 36

- 1.6. MOTOR CONNECTION 39

- 1.7. MANUAL CONTROL 41

- 1.8. PLC CONNECTION 43

- 2. AUTOMATIC CONTROL DESIGN 45

- 2.1. SIMULATION 46

- 2.1.1. Controller PS4-201-MM1 and SUCOSOFT 46

- 2.1.2. Four levels elevator application 55

- 2.1.3. Grafcet for simulation 60

- 2.2. GRAFCET FOR TEN LEVELS´ ELEVATOR 63

- 2.2.1. Inputs and outputs identification 63

- 2.2.2. Main grafcet 67

- 2.2.3. M1 – Level control 72

- 2.2.4. M2 – Button control 72

- 2.2.5. M3 - Door control 73

- 3. CALCULATIONS 76

- 3.1. COUNTERWEIGHT 76

- 3.2. MOTOR POWER 77

- 3.3. CONDUCTORS SECTION AND ELECTRICAL DEVICES DIMENSIONING 78

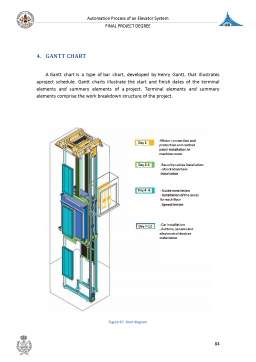

- 4. GANTT CHART 86

- 5. MAINTENANCE AND SECURITY 88

- 5.1. MAINTENANCE 88

- 5.1.1. Preventive maintenance 88

- 5.1.2. Corrective maintenance 89

- 5.2. SECURITY 89

- 6. PLOTS AND GRAFCETS 91

- 6.1. PLOTS 91

- 6.2. GRAFCETS 91

- 7. CONCLUSION 93

- 7.1. IMPROVEMENTS 93

- 7.2. ACHIEVEMENTS 95

- 9. BIBLIOGRAPHY 99

Extras din licență

PROJECT DESCRIPTION

1. PROJECT DESCRIPTION

1.1. BRIEF HISTORY OF LIFTS

The first reference of the use of lifts is the work of the roman architect Vitruvio, who said that Arquimedes built the firs elevator in 236 B.C. In medieval times, the lifts worked with the help of animals or manually to transport persons or materials between different levels. In its easiest way, it was built with a wooden box hanging from a wire.

But lifts as they are known nowadays are dated from the XIX century.

In 1823, in London, Burton and Hormer built what they called “ascending room”, which could elevate 20 persons at a height of 37 meters.

In 1853, Elisha Graves Otis invented the first emergency brake for lifts, which was actuated in case that the cable got broken, or the lift reached a high speed. The security device designed by Otis is very similar to one of the devices that are used nowadays.

In 1857, March 23, Otis installed his first elevator in New York through his company “OTIS”.

In 1880, the German inventor Werner von Siemens introduced the electrical motor in elevators.

In 1957, August 30, the first automatic system for doors was installed, what finished with the process of opening and closing doors manually.

In 1996, the company KONE built the first viable lift without machine room.

In 2003, ThyssenKrupp Elevators presented the “Twin” elevator: two cars in the same hole.

The World Trade Center, in New York (EE.UU), with its two towers of 110 levels, has 244 elevators with a capacity up to 4536 Kg and speed up to 488m/min.

1.2. OBJECTIVES OF THE PROJECT

The main goal of the project is to design an automatic control for an elevator system with 10 levels for a maximum of 6 persons (450Kg).

In order to demonstrate the functionally of the algorithm designed, a simulation has been made with the PLC PS4-201-MM1 for an elevator with 4 levels, principally due to the limitation of inputs and outputs of the PLC.

For the simulation, the goal is to design the GRAFCET and the program for this PLC using “Sucosoft”, whereas that for the case with 10 levels the goal is to design the GRAFCET for the automatic control, taking into account everything related to security devices.

A second objective is to design the electrical installation for the elevator, which involves the connection between the power supply, the motor and the PLC, the connection of the different devices to the inputs and outputs of the PLC, and the installation of light and power plugs. The design of electrical protection for motor and persons is also included.

Preview document

Conținut arhivă zip

- Automation Process of an Elevator System.docx