Extras din proiect

1. Introduction

The high cost of energy produced by traditional means polluting led humanity to move towards new sources of non-conventional energy, green energy.

Today there is a cumulative effort to make people aware of the impact of human life on our planet and the potential damage over energy use might have.

Various organizations (public or private) work together to master the energy costs and reduce CO2 emissions and introduce the Earth's atmosphere.

The first step in raising consumer awareness, is to understand reducing energy costs: electricity, gas, water, sewage. It is a process that happens at the moment when the consumer is becoming more educated about energy consumption, CO2 pollution, energy production from renewable sources and access to cleaner technologies.

Such energy cheaper and can be produced by using biogas produced from plant residues, animal manure, garbage, etc.

This project addresses how to produce renewable energy using dead leaves, crop residues from cleaning parks in Cluj-Napoca, mixed with household waste from student cafeteria restaurant complex.

The advantages are many, primarily because the raw material leaves a get free from those dealing with parks care because they do not spend the storage and transport of plant debris and leaves us as we take users with some special machines equipped with a leaf vacuum system and compacting them to reduce their volume, in some bags of biodegradable material.

Plant debris transport is short (less than 6 miles) low cost and low storage biodegradable bags is not polluting.

Green energy produced from plant residues and use of household waste is cheaper than energy produced classic student currently for complex supply and reducing carbon dioxide emissions due to reduced losses, reduce consumption, use energy more efficiently in system in peak hours.

The leftovers after biogas production is sold to farmers as fertilizer ecological thus making extra income, natural fertilizer and transport costs incumbent upon all farmers, without having to make extra expense for storing waste resulting the biogas plant and transportation to beneficiaries.

Purpose the project goal is to identify optimal solutions regarding the use of renewable energy, green, by biogas, a mixture ecological fuel with zero emissions resulting from anaerobic fermentation of dead leaves, mixed with sewage and garbage from the municipality of Cluj-Napoca, in order to better use vegetable waste from cleaning parks and the use of waste energy conversion for heating a student complex.

1.2 Objectives

"The plant for biogas production in Cluj-Napoca", pursues three main objectives:

- - reduction pressure on the environment due to ensure better waste management - from the collection of green waste, particularly dead leaves in city parks and municipal waste

- - productions energy (electricity and heat) using as the main raw material plant debris;

- a framework - crearea demonstration of good practice in this area.

The investment is financed by the Ministry of Environment and Climate Change in the project "Integrated Nutrient Pollution Control", funded in turn by GEF / World Bank, International Bank for Reconstruction and Development and the Romanian Government ofinanțat.

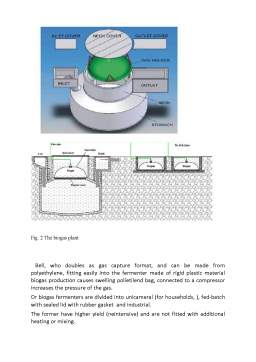

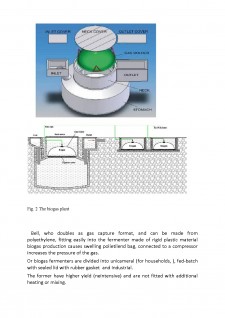

Referring to the work of biogas production, it can be mentioned that a biogas plant is a complex installation, consisting of a variety of elements.

The operation of such a plant depends largely on the types and quantities of raw material used.

Since there are a number of different types of raw materials of various origins, which are suitable for digestion in biogas plants, there properly, various techniques for treating these types of raw materials and many ways digester building and operating systems.

Furthermore, depending on the type, size and operating conditions of each biogas plant, various technologies for the conditioning, storage and utilization of biogas are possible to be implemented.

In terms of storage and use of residues from biogas production as they are primarily oriented towards its utilization as fertilizer.

1. Four large main steps describe the operation of a biogas plant:

- - Transport, delivery, storage and possibly pre-treatment of raw materials. The main raw material is the dead leaves and garbage that are subjected to grinding and then stored in silos on the site, without having undergone any treatment other treatment before being inserted into the digesters. Also, to provide the necessary supporting bacterial fermentation, the fermentation before inserting chopped leaves the digester will be primed with sewage and garbage.

Their proportion of the total quantity of raw materials, ranging after start up also, depending on the parameters of the fermentation process to establish optimal amount;

- - Production biogas, where the investment analyzed by anaerobic digestion, fermentation in tank (digester)

- - Treatment (especially desulphurisation) and storage of biogas produced. For the present project, biogas will not store, only to the extent provided useful volume of the digester roof, being used to produce electricity and heat directly on site. Before targeting module cogeneration, biogas will be desulfurized in a first step directly into the digester, biological method, then, purifies a coal asset in installation.

Bibliografie

Guvernul României, Ministerul Mediului și Dezvoltării Durabile, 2008: Strategia Națională pentru Dezvoltare Durabilă a României Orizonturi 2013-2020-2030.

Institutul Național de Statistică, 2012. Anuarul statistic al României.

Badea R., Ștefănescu S.L.: Agricultura ecologică în România, legislație, oportunități, impedimente.

Ferber E., Rutz D. (2011) Criteria to assess biogas investments: Guidelines for financing institutes and investors.

Rusu, T., Bejan, M. Deșeul - sursă de venit. Editura MEDIAMIRA, Cluj-Napoca, 2006)

Fizeșanu Silvia, Cătuneanu, T., Gnandt, Fr., Bejan, M.Știință și inginerie, vol. 5, „Creșterea calității vieții prin realizarea de energie regenerabilă din deșeuri organice”,Editura AGIR, București, 2004)

V Giurgiu, 1995, Protejarea și dezvoltarea durabilă a pădurilor României, Editura Arta Grafică București

Gh Mohan , A Avram , 1989, Valorificarea resurselor vegetale în gospodărie și industrie, Editura Tehnică București

Preview document

Conținut arhivă zip

- Biogas - energy efficency.doc